SERVICES.

-

On Demand.

We specialise in small batch on-demand manufacturing.

Minimise your component inventory whilst still being able to ramp up with demand.

-

Bridge Manufacture.

We can supply the initial production runs of your components so you can test and refine products before committing to injection moulding tooling.

-

Local Manufacture.

With no tooling and parts ready within a few days additive manufacturing can help companies decentralise their manufacturing and remove their reliance on long distance shipping and compromised supply chains.

-

Rapid Prototyping.

We can print your prototypes in 2-3 days, develop and iterate faster. Use the same process from prototype to production

-

Customisation.

One of the many benefits of 3D printing is that each component can be modified so each one in a batch is unique. This could be as simple as adding a unique code or as complex as modified geometry.

-

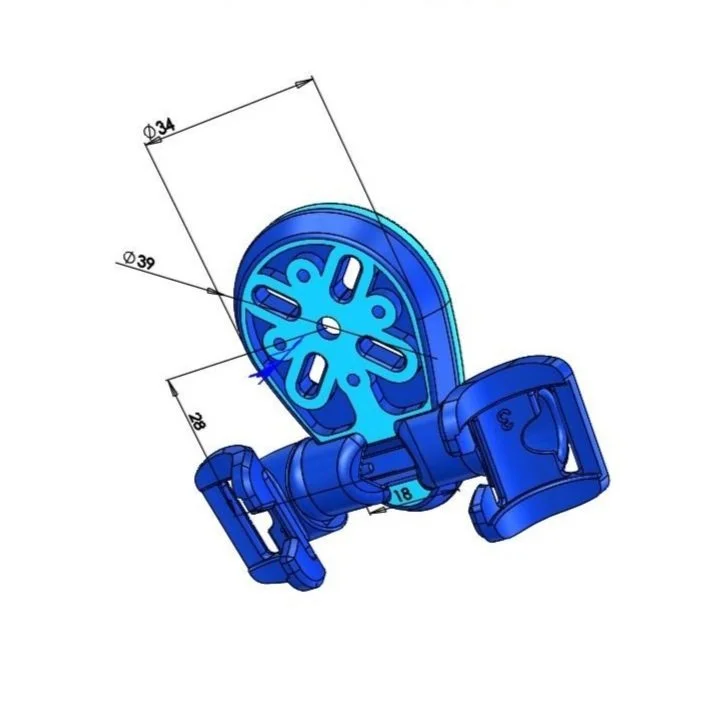

Design & Development.

Our experienced industrial designers offer complimentary advice to optimise design for additive manufacturing (DfAM).

Please enquire if you need a full design and development service for your project.

-

Finishing.

Our standard finishing includes black dying and shot peening which provides a tough scratch resistant light textured, semi matte finish.

For other colours with we also offer Cerakote using our finishing partners. colours available

-

Assembly & Shipping.

As well as component supply we also offer assembly and kitting services.

Orders are dispatched as standard on a next day tracked service.

Other services available on request.